Resources

Find helpful articles, guides, and reports to help you grow your self-service retail business.

Webinars

The Year of the Touchscreen: How New Readers Are Gearing Up to Change the Vending Landscape

Customer Engagement

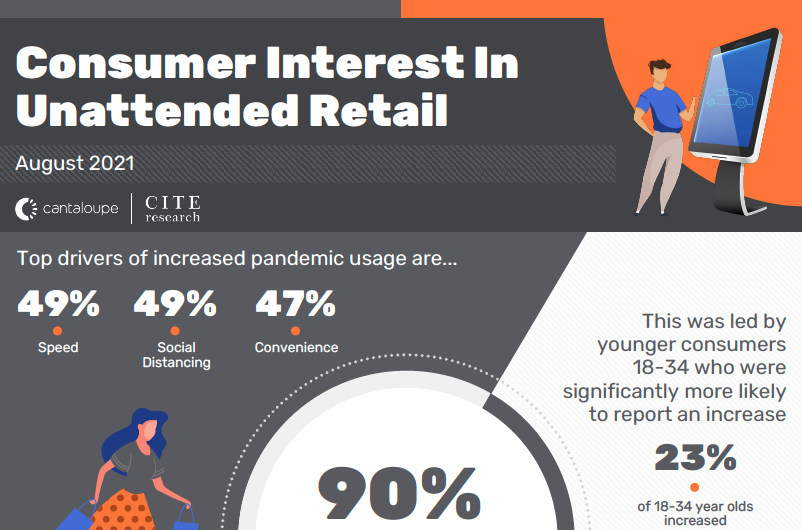

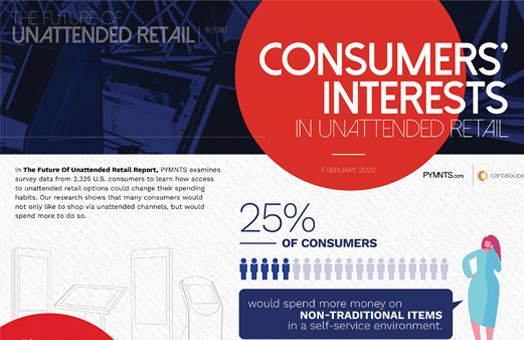

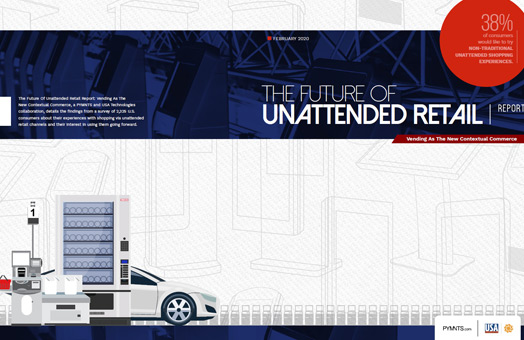

Infographics

Unattended Shoppers in 2020: Who They Are and What They Want

Customer Engagement

Webinars

Learn the 3 Biggest Product Merchandising Pitfalls and How to Avoid Them

Customer Engagement

Webinars

Cash Accountability: How 5 Minutes A Day Can Increase Your Bottom Line

Business Management

Webinars

Micro Markets: How to Create Profitable Locations with 50+ Employees

Business Management

Webinars

Office Coffee Service: 5 Ways to Drive More OCS Profits with Technology

Business Management

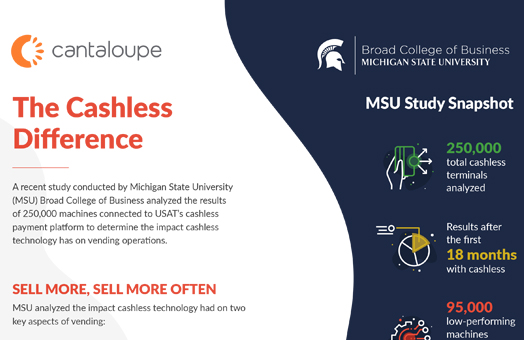

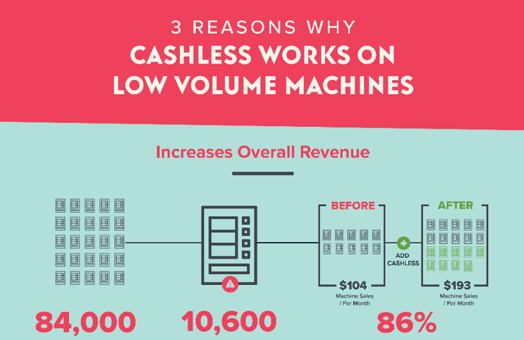

Infographics

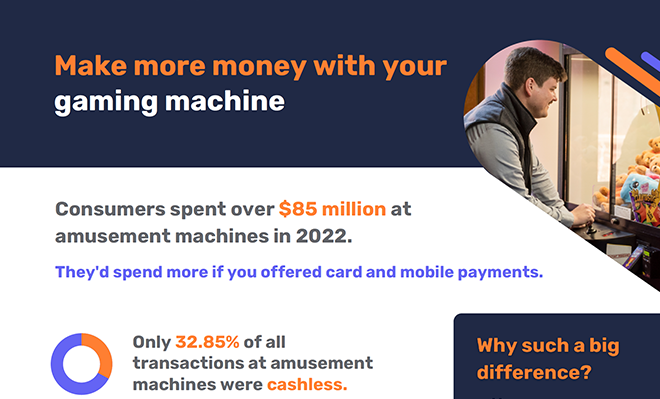

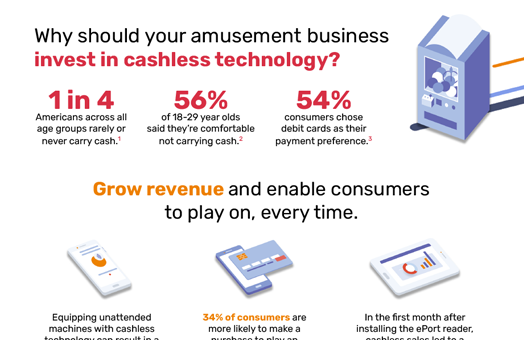

3 Reasons Why Amusement Businesses Should Invest in Cashless Technology

Payments

Want to stay in the know? Subscribe to our newsletter!